First United Methodist Church

Dalton, Georgia

Parkey Organbuilders

Berkeley Lake, Georgia

View an enlarged cover

View the Stop List

Dalton First United Methodist Church is located in Dalton, Georgia, an active community located in northwest Georgia about 30 miles from Chattanooga, Tennessee. Dalton remains an active producer of carpets and now hardwood and tile flooring. The industry has been very kind to the community providing an active economy.

First United Methodist has enjoyed an active music program for many decades under the leadership of several fine musicians. The church had a new pipe organ installed in 1982, and that organ served the congregation well for the time of its installation. We have been fortunate to have them as a client over the years for maintenance and service.

In 1991, the church did a major expansion of the facility to include a new chapel, fellowship hall, and atrium. In that expansion, the church added to the end of the sanctuary behind the choir loft. The new section remained unused and segmented from the main sanctuary for over 25 years. Over the years the choir continued to grow and the deficiencies of the organ became more pronounced. By the late 90s, Peter Infanger, director of music ministries at the time, had initiated several project discussion on expansion of the choir loft and expansion of the organ. In fact, the new console we installed in 2008 was prepared for additional controls and drawknobs. In 2015, the church moved forward with a major plan to update facilities and renovate the sanctuary to now utilize the additional space for the installation of the pipe organ. The choir loft nearly doubled in size and the pipe organ was now moved into a central axis location. Part of the changes also included new walnut cases and facades for the organ, which provide a more traditional style appearance appropriate to the church’s architecture.

The church incorporated a number of improvements to the chancel and sanctuary space for reverberation and tonal egress. The new choir loft is floored in ceramic tile, as are the floors under the pews. The 1950s acoustical material was removed from the sanctuary ceiling. Relocating the organ to the new sanctuary addition added additional floor space in the choir loft. All of the changes created a much more reverberant space while still rendering an excellent space for the spoken work.

Though a new console and relays were installed in 2008, the windchests were now showing their age at 35 years. To reconfigure the organ, new windchests and swell boxes would be in order. The church requested proposals for a new organ retaining pipework of the current organ. In 2015 we signed with the church for Opus 16 of our firm. Though pipework was retained, several stops were relocated, scaling was addressed, and several additions were planned. Voicing and scaling were revised to correct the issues of the cantilevered flower box design so well known in the 60s and 70s. Some mixtures were lowered in pitch and some reassigned to new locations. A new complete mixture was built for the Swell Division. All of the retained pipework was re-voiced and regulated for the changes in the room and specification placement. Attention was given to the color of the stops as well as their balance.

The organ is constructed with electro-pneumatic slider windchests, with electro-pneumatic unit action windchests for select unit stops. The main winding regulators are single rise box regulators for very gentle wind response. Swell boxes are tight and well insulated for a wonderful dynamic response range.

We retained several 8′ foundation stops of ample scale from the original organ. However, middle and upper pitch stops were rescaled for a more even and cohesive build up. The bright and brittle sound with mixtures was magnified by the original windchest layouts and flower box configuration. In the new organ configuration, the specially designed chamber provides ample space for the footprint of the organ to remain on one level for tuning stability. The walls were specially constructed for maximum reflection. Pipe ranks were arranged in a far more appropriate configuration with 8′ pitches located nearest the tone opening and upperwork moved to the rear of the chambers for better tonal blend and easing of the brilliance of upperwork. New full-length pipes corrected the bass response in the room. In addition, the new pipes also gave a way to complete the new cases and facades.

Jeff Harbin, the director of music ministries and organist, has a wonderful understanding of the worship process. As we build pipe organs, we must consider the wide range of music available and how each organ will navigate the ability to provide that music. One can study and examine the different styles of organ construction and emulate different options. The organs that we have in America have come to reflect who we are and the diversity of our society. However, one of most demanding jobs of the organ is the ability to lead congregational singing. To have the scale and resources of an organ for a skilled musician to call upon will provide one of the many intimate experiences for the person in worship. I have often shared with my organists the thought that you should play the hymns with respect and flourish, and the congregation will embrace anything else you provide. During the course of construction and tonal finishing, I had many conversations with Jeff Harbin, the current director of music ministries and organist, concerning the organ and its design. Jeff is a well-respected musician and delight to work with. He understands the importance of hymns and how to structure his playing to encourage and lead congregational singing.

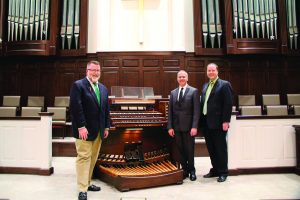

Peter Infanger, former director of music ministries and organist at First United Methodist Church, provided very good insight and pushed for the organ and the additional space that the church now enjoys. John Wigal, organist and choirmaster of the Church of the Good Shepherd on Lookout Mountain, Tennessee, provided a careful guiding hand as the consultant during the transition between Peter Infanger and Jeff Harbin. All three remained clear on the role of music and the organ with its relation to worship, and I think the final instrument is an excellent example of work and cooperation. Our firm is fortunate and pleased to have been selected as the builder for this project. We extend our appreciation to each of these gentlemen and the Organ Committee for their confidence and cooperation. My dear friend and colleague, Alan Morrison, provided the dedication recital to a packed house on March 17, 2017. The recital was stunning! All are to be commended for the work and presentation of Parkey OrganBuilders Opus 16.

Phil Parkey

President and Tonal Director

PARKEY ORGANBUILDERS STAFF

Michael Morris, design and layout

Philip Read, shop supervisor and installation

Kurtis Robinson, CNC operations and windchest construction

Johann Nix, master woodwork (windchests and console)

Chris Bowman, voicing and tonal finishing

Otilia Gamboa, leather operations and wiring

Kathy Yi, office manager

Keith Williamson, scheduling and service

From the Director of Music Ministries and Organist

In December 2014, I received a call to serve as director of music ministries and organist of the First United Methodist Church in Dalton, Georgia, a town known as the “Carpet Capital of the World.” Established in 1847, this northwest Georgia congregation, a flagship church in the North Georgia Conference, has long been recognized for the quality of its music ministry, which includes choirs for all ages, preschool through senior adults.

The current sanctuary was built in 1951 to meet the needs of this active and growing congregation. It is not known what organ was first utilized in the new building, although the church had installed a modest two-manual, nine-rank M.P. Moller (Opus 6559) in its previous location in 1937. It’s quite possible that this fairly new instrument was moved when the church relocated. In 1962, the congregation purchased a three-manual electronic organ that it would use over the next two decades.

In 1979, Donna Jean Bassett was recognized for 25 years of continuous service as church organist. She expressed thanks for her gift, then added “now let’s work to getting a pipe organ.” Her dream came to fruition in 1982 when a three-manual, 43-rank instrument, built by a reputable American organbuilding firm was installed. Robert MacDonald performed the dedicatory recital.

The organ was installed making full use of the limited space that was available. The left chamber housed the Pedal division, with the Swell and Choir both located on the right. The Great was divided on two “flower box” windchests mounted above the choristers’ heads on each side of the chancel cross. Many of the bass pipes had to be mitered, with the bottom octaves of both the Pedal Principal and Gemshorn constructed in the Haskell style. For this reason, the organ’s bass line was always weak and insufficient for the space. As was typical of the period, the voicing was bright and high-pitched mixture stops were plentiful.

In the early 2000s, burdened with an aging facility, a limited chancel space that offered almost no flexibility and an organ with obvious deficiencies, the church began exploring the possibility of a large-scale capital campaign. This was initiated during the 20-year tenure of Peter Infanger, director of music ministries and organist. With Peter’s guidance, the groundwork was laid for a major renovation project that would finally commence in 2015.

Mr. Infanger announced that he was leaving Dalton at the end of 2012 to accept a new position teaching at Mississippi State University. Over the next two years the church would be served by several interim organists and choirmasters. John Wigal, from the Church of the Good Shepherd in Lookout Mountain, Tennessee, was brought onboard to serve as organ consultant. Several well-respected organbuilding firms were asked to submit proposals for the relocation, enlargement, and improvement of the existing instrument.

For approximately two decades, Phil Parkey and his team from Atlanta had maintained the church’s pipe organ. He had “come to the rescue” on many occasions and built a new console for the instrument in 2008. The church building committee felt very comfortable with Parkey OrganBuilders and awarded the contract to the company in early 2015.

I personally have known Mr. Parkey since 1995 and have always had a tremendous appreciation for his quality work and attention to detail. He and his team did not fail to deliver on this project, the company’s Opus 16. To help the church be good stewards of their financial resources, Mr. Parkey and his team carefully and artistically reused much of the prior organ’s pipework. The majestic new facade, with its rich woodwork and polished tin pipes, leads the worshipers’ eyes upward to focus on the centrally located chancel cross. New slider action windchests were constructed so that the Swell and Choir could be divided on the left and right, respectively. A hauntingly beautiful French Hautbois was added to the Swell. A complete and robust flute-based Cornet also now graces this division. The beauty of these solo timbres is enhanced by the new Swell tremulant. Finally, the Swell chorus was completed with a new, lower pitched Plein Jeu IV, perfect for choral accompaniment. The previous organ’s Scharf III was relocated to a more appropriate home in the Choir division where it now functions perfectly. Also added to the Choir division was an 8′ Geigen Diapason, which lends gravity to the ensemble; this stop has also proven useful as both a solo and accompaniment voice. The 16’´ Gemshorn was expanded by twelve pipes to provide an 8’´accompaniment stop for the Great division. Four existing pipe ranks received completely new bass octaves to provide a solid foundation under the organ. A larger blower was installed so that the 50-rank instrument would be winded adequately. All of the pipework, both new and old, was properly scaled and voiced for the improved acoustics of the renovated sanctuary. The organ thrives in its new environment!

Although a purely pipe instrument, the organ possesses 300 levels of memory, a record and playback system controllable via iPad, and full MIDI compatibility. It is truly a blend of historic and modern technologies—an organ for the 21st century! One unique feature is a “Smart Resultant” in the Pedal division. It normally quints the bottom twelve notes of the 16’´ Bourdon. However, it switches to the 16′ Principal when the two drawknobs are drawn in conjunction, giving the organist “two stops for the price of one.”

Alan Morrison played a magnificent inaugural recital to a full house on the evening of St. Patrick’s Day, March 17, 2017. Since that time, the new Parkey organ has been the “talk of the town.” Nothing but positive comments have come from the congregation, who absolutely love their new organ. They realize how blessed they are to have such a magnificent instrument lead them in praising God “from whom all blessings flow.”

Jeff Harbin

A Kimball in the Wilderness

A Kimball in the Wilderness

Plainfield United Methodist Church

Plainfield United Methodist Church